Adeno-associated virus (AAV) vectors have become the dominant delivery platform for gene therapies, with several FDA-approved products and many more in clinical trials. Yet upstream manufacturing remains a persistent bottleneck. Inconsistent cell line performance, variable transfection efficiency, and scale-up challenges create titer variability that lengthens time to clinic and increases costs.

Addressing these upstream challenges requires more than incremental improvements. Process development teams need reproducible cell culture systems, high-purity plasmid preparations, optimized transfection protocols, and qualified reagent supply chains. When these elements align, predictable titers, smooth tech transfer, and faster paths to clinical manufacturing are achievable.

Characteristics of High-Performing AAV Programs

Programs that achieve high, reproducible titers share common characteristics. They adopt HEK293 suspension platforms in chemically defined media, use high-quality plasmids that are thoroughly tested, and optimize transfection protocols using high-efficiency transfection reagents that can reduce plasmid DNA input and the number of bioreactors needed to lower costs. Additionally, they implement design-of-experiments (DOEs) to identify critical process parameters and use real-time monitoring to detect deviations early.

Reagent supply also drives performance. cGMP-grade materials, complete quality documentation, and qualified backup suppliers reduce the risk of batch failures and timeline delays. When these upstream elements are controlled, the entire upstream workflow—from cell expansion through AAV harvest—becomes predictable and scalable. Understanding where this predictability originates requires a closer look at the upstream workflow.

Understanding the AAV Manufacturing Process

Upstream processing directly influences final viral vector yield. Titer variability largely stems from this stage, with downstream purification unable to correct upstream issues. Four core processes define the upstream workflow, and each must be controlled to achieve reproducible results.

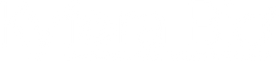

Cell culture is the foundation. Usually, HEK293 suspension-based platforms grown in chemically defined media are used. Maintaining overall cell health (including passage number, contamination, and viability) is essential at both small and large scales to ensure consistent growth and productivity. When scaling up, critical parameters include bioreactor conditions such as pH, dissolved oxygen, and agitation, all of which affect cell health and performance. Controlling these variables ensures that cells are in optimal condition to take up DNA and produce viral vectors.

Plasmid production comes next. The standard three-plasmid system—transfer, Rep/Cap, and helper—requires high-purity preparations free from endotoxins and other contaminants and with minimal residual host DNA and proteins. Sequence verification is non-negotiable for producing high titers.

Transfection is where plasmid DNA enters the cell. AAV workflows use transfection reagents such as polyethylenimine (PEI) or KyFect™-AAV to form complexes with DNA at a defined nitrogen-to-phosphate (N/P) ratio. Complexation conditions—DNA:reagent ratio, ratio of total plasmid DNA to cells, and complexation—directly affect complex size, uptake efficiency, and ultimately, viral titer.

Vector production and harvest follows transfection. Cells produce AAV particles over a defined window—typically 48 to 96 hours post-transfection. Harvest timing is set empirically based on studies that track vector accumulation and cell viability. Once optimized, this timing remains fixed across production runs.

Underlying all four processes is reagent quality. Qualified, cGMP-grade materials, complete QA documentation, and vetted second-source supplier options reduce batch risk and support regulatory filings. Following harvest, the workflow transitions to downstream operations: clarification, purification, formulation, and analytical release testing.

Key Upstream AAV Manufacturing Challenges

Five critical areas account for most upstream variability. Controlling each requires distinct technical strategies and process discipline.

Cell Line Development & Stability

Host cell selection is the first technical decision in any AAV program. HEK293 cells remain the industry standard because they support high transfection efficiency, grow well in suspension, and scale reliably from shake flasks to bioreactors.

Establishing a stable production system starts with cell banking. A fully characterized master cell bank (MCB) and working cell bank (WCB) provide the genetic consistency needed for reproducible manufacturing. Characterization includes identity testing, mycoplasma and sterility assays, and baseline productivity metrics. Once banked, cells must be cultured under tightly controlled conditions.

Passage number is a critical variable. Extended passaging can lead to genetic drift, which reduces transfection efficiency and lowers titer. Seed train parameters also require control: viable cell density (VCD) at inoculation, doubling time, and viability at transfection should remain within defined ranges across production runs.

Contamination poses another risk. Even low-level mycoplasma infection can degrade cell metabolism, reduce vector yield, and compromise product quality. Regular testing and adherence to aseptic technique are essential safeguards. When cell banking, seed train management, and contamination control are all in place, the upstream system becomes predictable and scalable.

Plasmid Production & Quality

AAV production usually utilizes a triple plasmid system. The transfer plasmid carries the transgene of interest. The Rep/Cap plasmid encodes the replication and capsid proteins necessary for the production and assembly of the viral capsids. The helper plasmid provides adenoviral genes required for replication. Each must be produced at high purity and must be combined at a defined mass ratio for successful, high viral vector yield.

Plasmid quality has a direct impact on transfection efficiency. A high supercoiled fraction ensures efficient nuclear entry and expression. Low endotoxin levels prevent cytotoxic effects that reduce viability and titer. Minimal host-cell DNA and protein reduce downstream impurity burden. Standard release criteria include sequence verification, endotoxin quantification, and purity measurement via A260/280 ratios.

Batch-to-batch variability in plasmid preparations can cause significant decreases in titer. To achieve consistency, every step—fermentation, lysis, clarification, and chromatography—must be controlled. Once validated, specifications for supercoiled percentage, A260/280, endotoxin levels, and concentration are locked across lots.

Because each plasmid contributes differently to AAV production, choosing the correct ratio is essential for yield, infectivity, and packaging efficiency. Optimal ratios vary by serotype, reagent chemistry, cell density, and scale.

Cell Culture Optimization & Scalability

Scaling from flasks to bioreactors introduces variability. Cell density, viability, and nutrient availability shift with volume. Shear stress, oxygen transfer, and mixing times affect physiology differently at scale.

The choice between adherent and suspension culture also impacts scalability. Suspension systems offer better scalability but require proper adaptation and clone selection to maintain productivity.

Media composition and feeding strategies must be optimized. Basal media should support high cell densities without depletion or toxic metabolite buildup. Feed strategies—bolus, continuous, fed-batch—must align with metabolic needs.

Contamination risk increases with scale, requiring robust aseptic technique, cleaning validation, and environmental monitoring.

Successful scale-up depends on identifying scale-dependent parameters early and optimizing bioreactor settings at each stage to maintain predictable performance.

Plasmid Transfection Efficiency

Transfection efficiency determines final functional titer. Even small deviations in DNA:reagent ratio, DNA amount, or cell readiness can significantly shift results.

Critical parameters to optimize:

DNA:Transfection Reagent Ratio

Small matrices are screened to determine the optimal ratio. The N/P ratio or equivalent metric is recorded and locked for future runs.

Complexation Preparation

Mixing speed, complexation time, and transfer timing are optimized to prevent shearing or aggregation.

Complex Attributes

Hydrodynamic size and zeta potential confirm optimal complex formation.

Cell State at Addition

Cells must be in log phase, >95% viability, and 2–3 million cells/mL.

Media

Serum-free, antibiotic-free media are recommended during complex formation.

Plasmid Stoichiometry

The triple-plasmid ratio and mixing order must be optimized for scale.

Timing to Harvest

Reporter assays or qPCR help determine optimal harvest windows.

Controls & Readouts

Positive, mock, empty-vector, and reagent-only controls ensure consistency.

By standardizing these variables early, run-to-run variability decreases and scalability improves.

Supply Chain Reliability & Raw Material Consistency

Raw material variability is one of the most underestimated sources of batch failure. Small differences in plasmid purity, media composition, or reagent performance can shift viral titer and quality.

Vendor qualification – cGMP documentation, CoAs, and change-control notifications are required.

Incoming QC – Every new lot should be tested at small scale before use.

Locked specifications – Critical attributes must be defined and enforced.

Lot tracking & trending – Performance data should be trended to detect drift early.

When supply chain management is treated as a technical discipline, programs achieve greater stability, fewer deviations, and predictable timelines.

How Kyfora Can Support Your AAV Workflow

Upstream manufacturing defines the performance ceiling for AAV programs. By controlling cell culture, plasmids, transfection, and harvest early, lower cost per dose and faster time to clinic can be achieved.

Kyfora Bio, backed by Polysciences’ 60+ years of chemistry expertise, provides high-performance transfection reagents and bioprocessing solutions designed for high-efficiency transfection and high AAV yields. Our portfolio includes research-grade and cGMP-grade PEI, liposomal formulations, and our newly released KyFect™-AAV, designed to improve titers, reproducibility, and scalability. We also offer enhancers like AmpliFect™, which boosts viral titers by >2×.

Beyond reagents, we provide supply chain reliability, full documentation packages, proactive inventory management, and technical support for optimization and troubleshooting.

Request technical support for your AAV workflow.

Contact our team to discuss your upstream manufacturing challenges, request samples, or schedule a technical consultation.